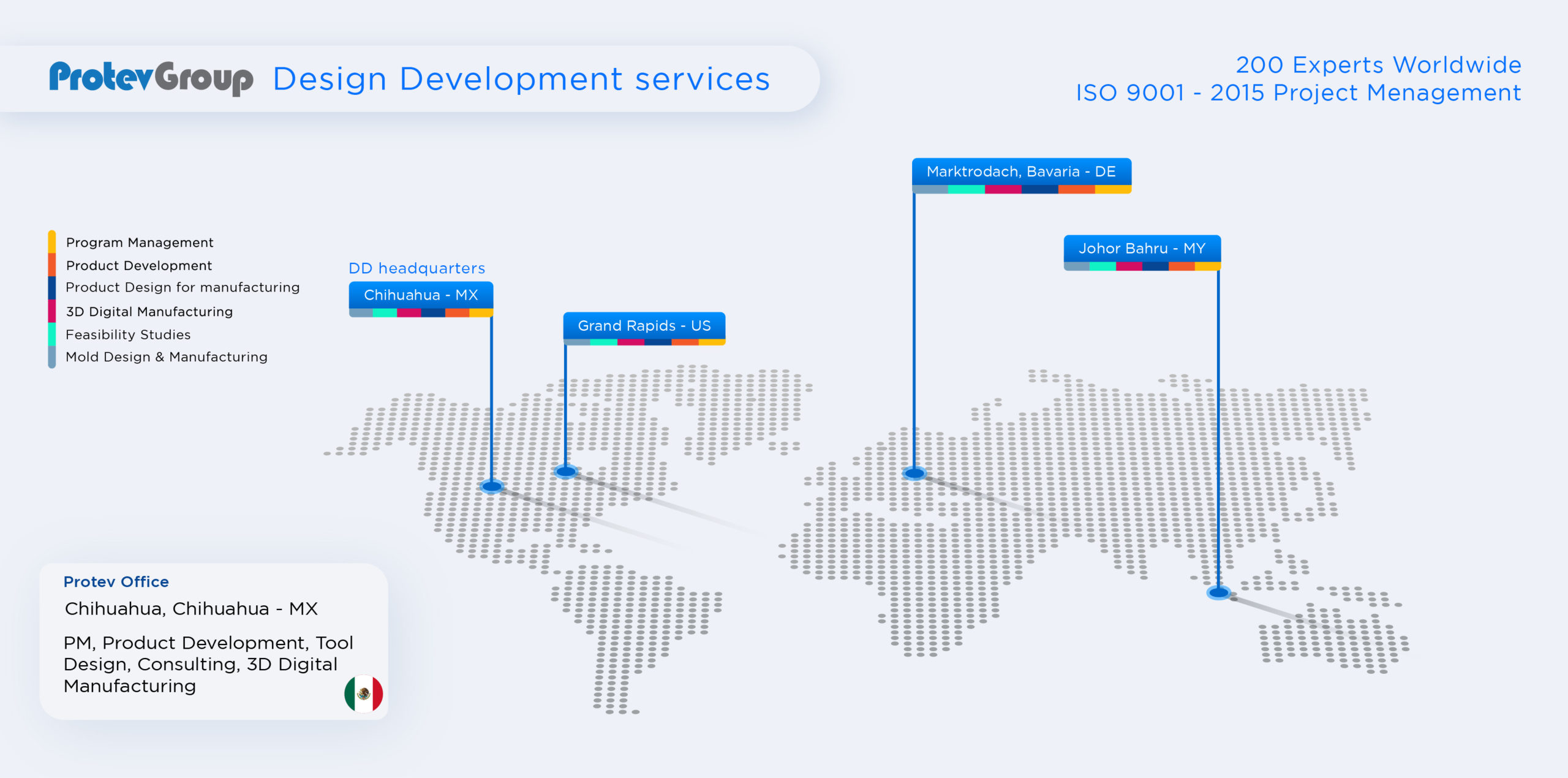

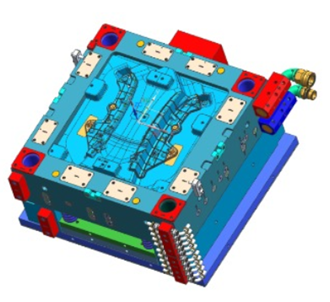

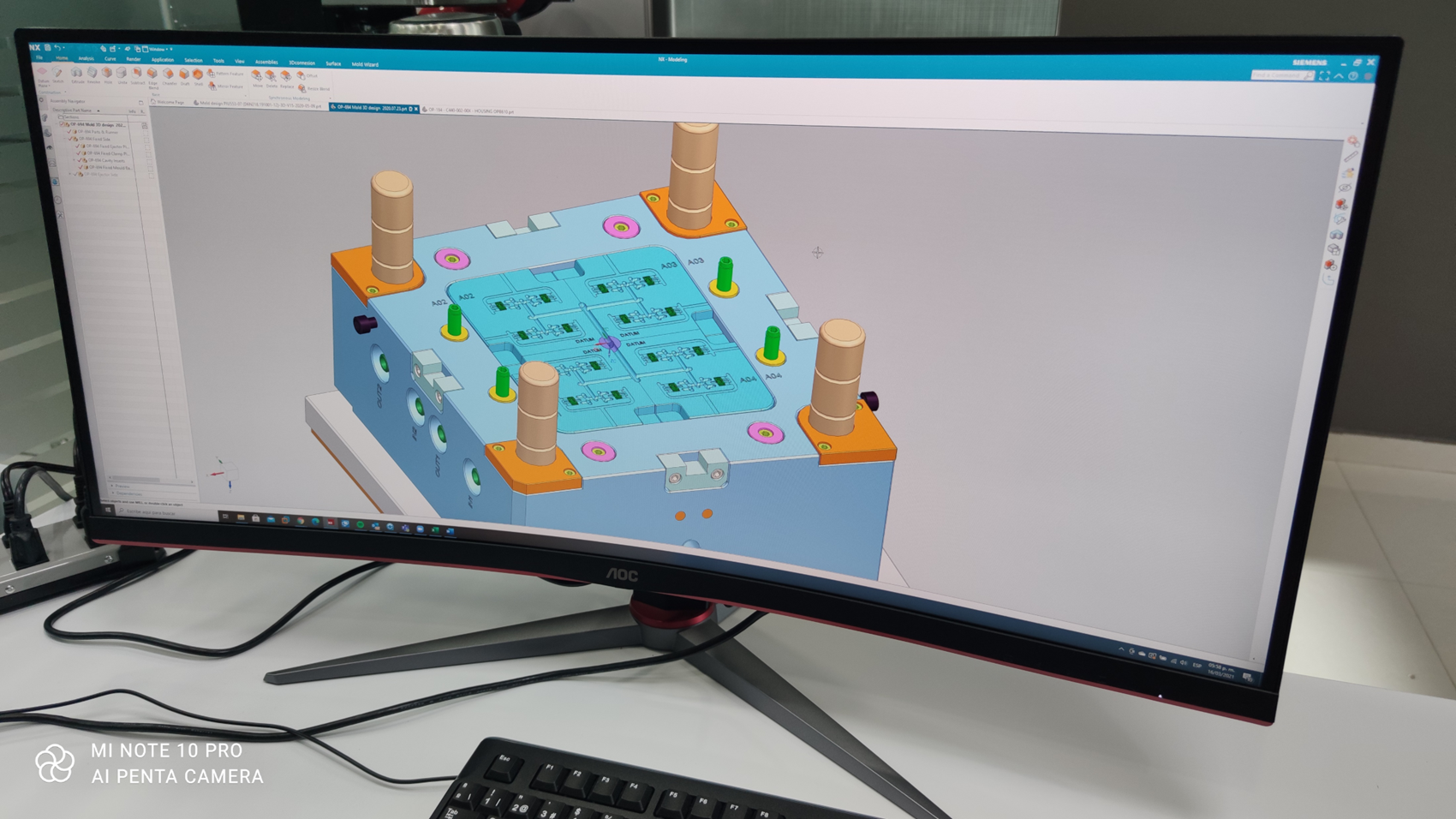

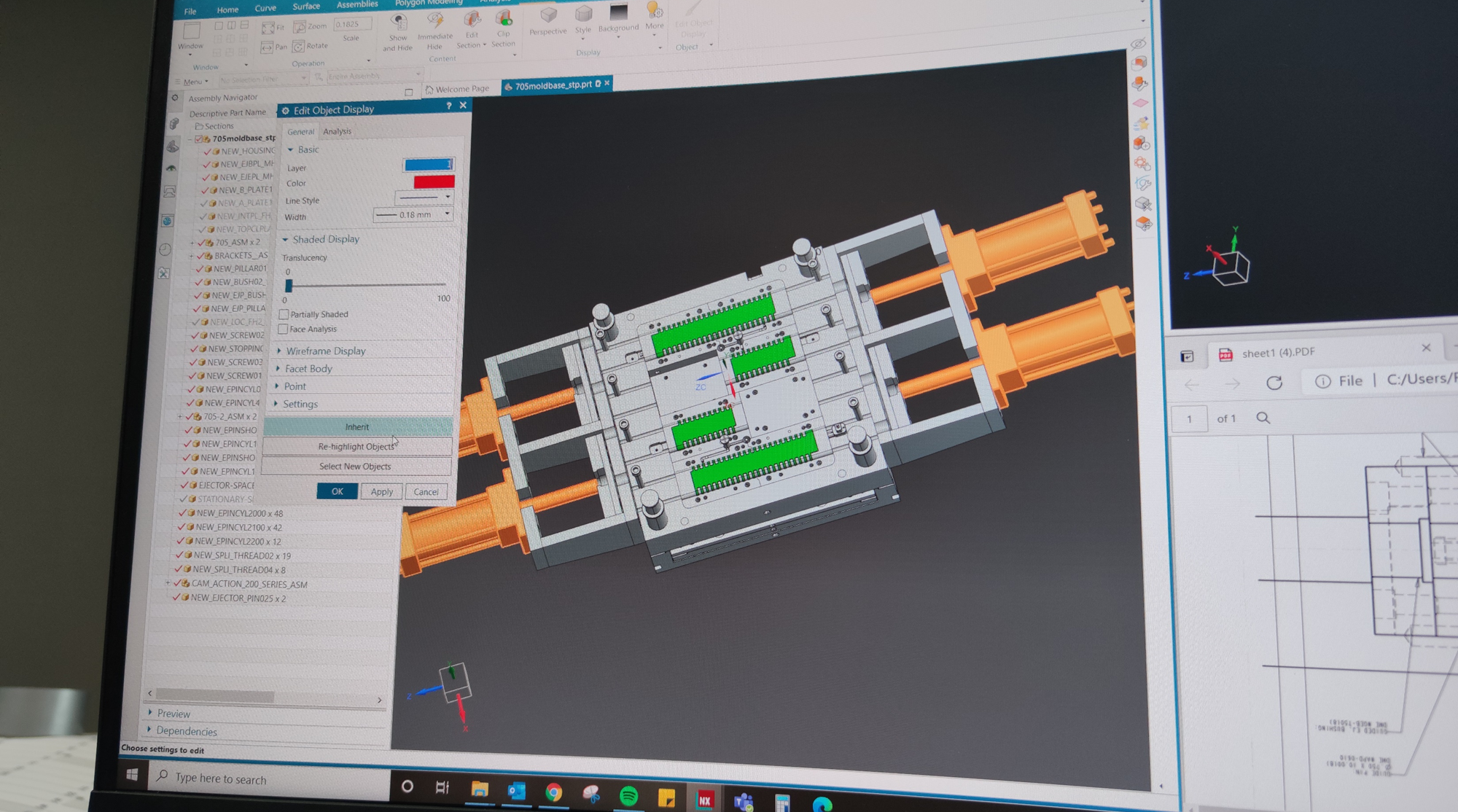

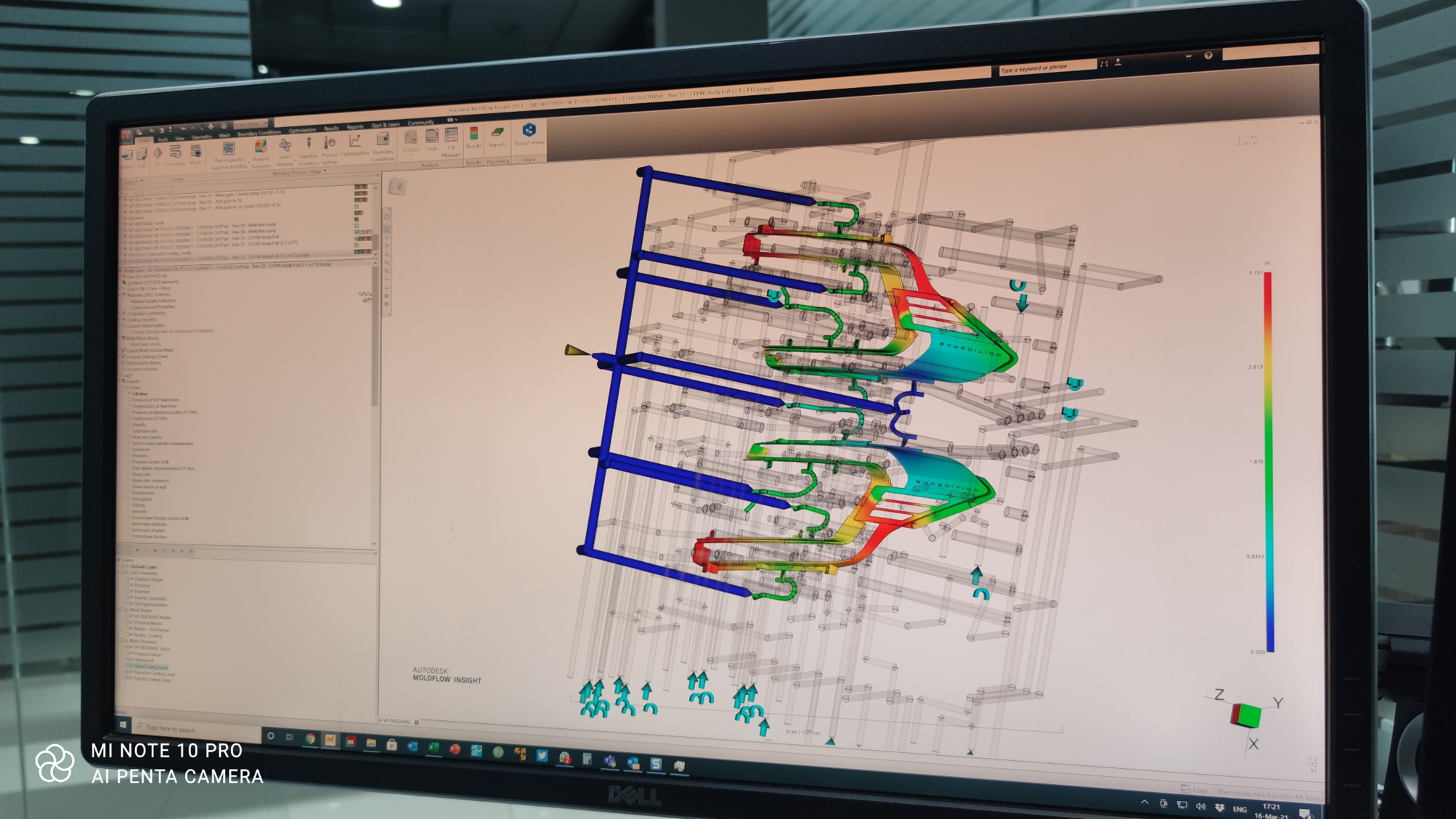

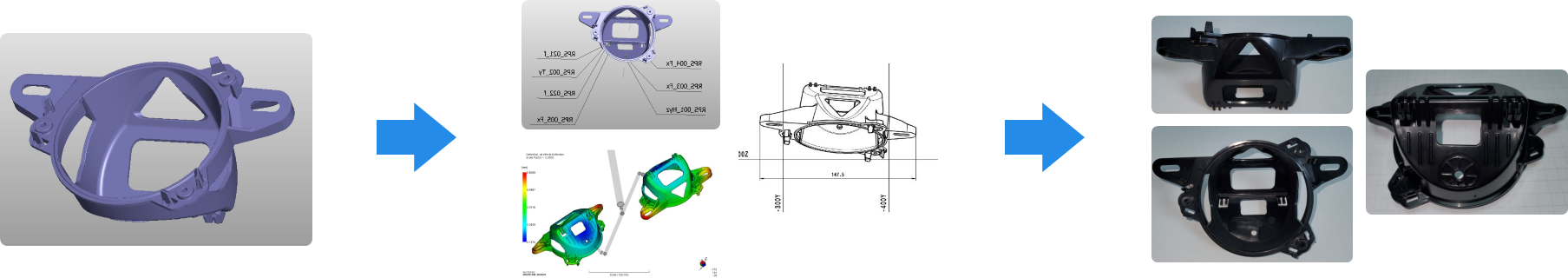

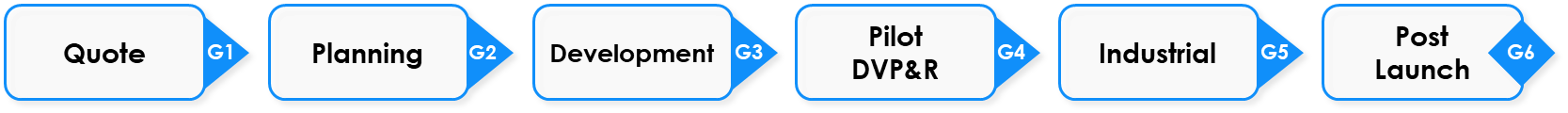

From an idea, a drawing or simply a sketch on a piece of paper, we can develop your design from cradle to production with the latest tools available in a modular approach.

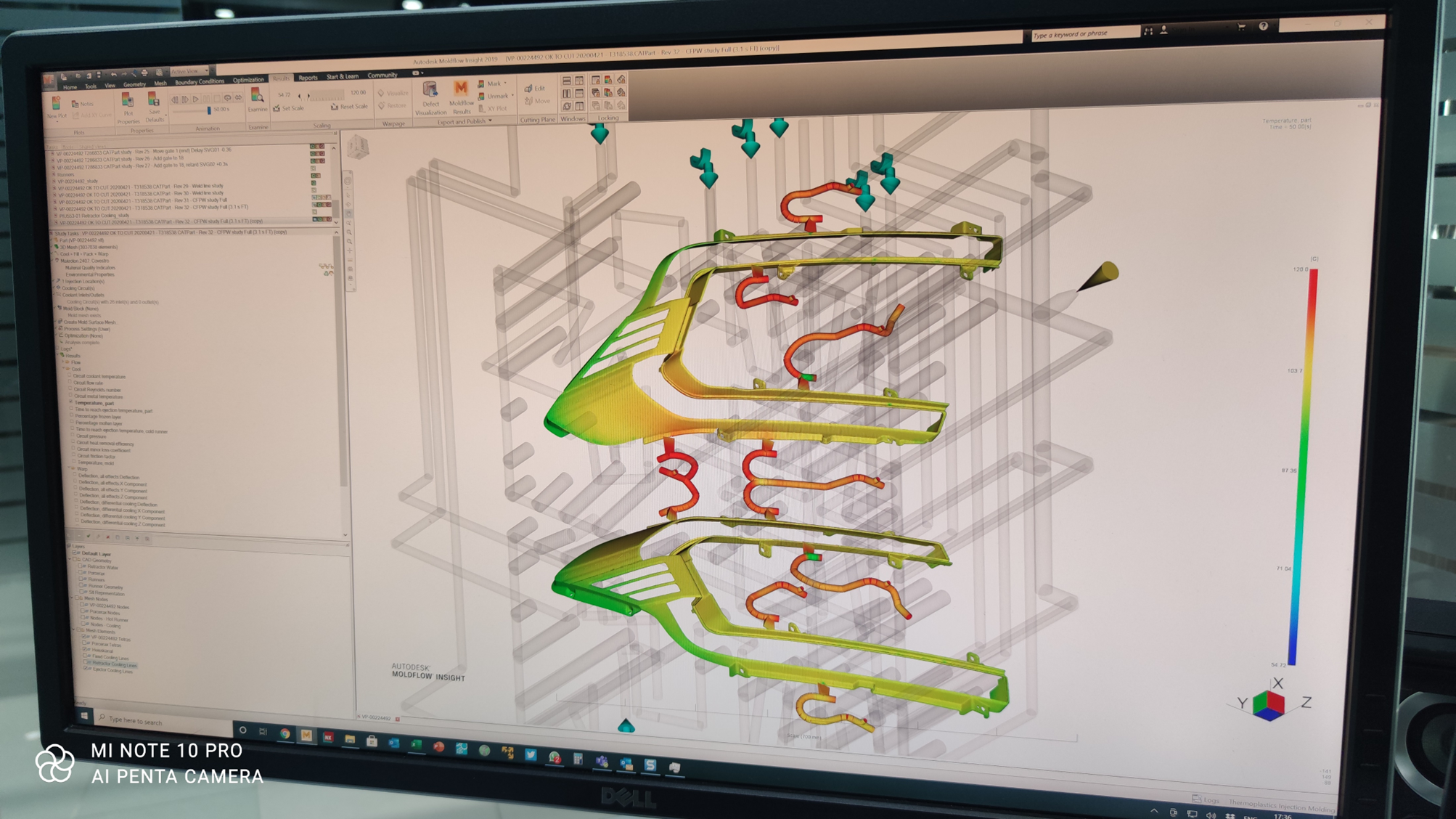

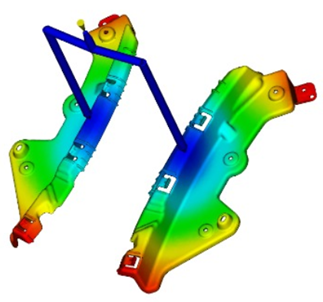

We can assist you with the full design, or we can help you analyse your design and recommend improvements to make it better to assemble, fill and manufacture.